MODULAR SELF ELEVATING PLATFORMS FOR SALE I DIRECT OWNER TO SHER WORLDWIDE

Contact Sher Worldwide #sw for inspection and offer submission

Product Number: SW-SEP-JCF-INTRO / SW-SEP-JCF-7 / SW-SEP-JCF-9.519th May 2025 - MODULAR SELF ELEVATING PLATFORMS FOR SALE I DIRECT OWNER TO SHER WORLDWIDE THE OWNER: Company Founded: Mid-1900s in Europe Global Reach: Supported by a worldwide network of agents Core Business & Offerings: Specialization: Fully modular floating and self-elevating marine equipment. Ideal for: Inland, port, and nea

Category: 17. Jack Up Rigs, MOPU, Jack Up Barges, Drill Ships, Land Rigs, Self Elevating Platforms

MAKE AN ENQUIRY

19th May 2025 -

MODULAR SELF ELEVATING PLATFORMS FOR SALE I DIRECT OWNER TO SHER WORLDWIDE

THE OWNER:

-

Company Founded: Mid-1900s in Europe

-

Global Reach: Supported by a worldwide network of agents

-

Core Business & Offerings:

-

Specialization: Fully modular floating and self-elevating marine equipment.

-

Ideal for: Inland, port, and nearshore operations.

-

Fabrication: Strategically located at multiple facilities across Europe, the Middle East, and Asia.

-

Stock & Delivery: Inventory kept in strategic locations ensuring quick client service and short delivery times.

-

Global Projects: Recently completed projects in Asia, Europe, Africa, the Arctic region, and South America.

-

Comprehensive Services:

-

Design and improvement

-

Product support

-

Fabrication to stock

-

Sale

-

Expert engineering support

-

-

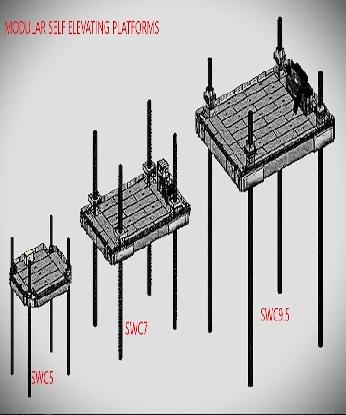

PRODUCT RANGE: UNPARALLELED VERSATILITY

-

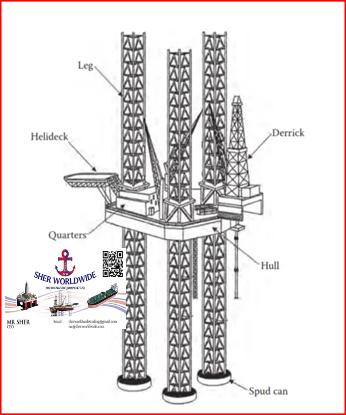

Jack-Ups:

-

Standard range: 80 to 1000mT elevating capacity.

-

Includes: The world's most capable modular jack-up.

-

Future-ready: Designs complete for a semi-modular monohull, capable of operating in over 60 meters water depth with a 2000mT payload.

-

-

Self-Elevating Platforms:

-

SW-C5 Series Self-Elevating Platforms:

-

Proven Success: Ideal for geotechnical services and inland marine construction works.

-

Robust Design: Offers a 15 t/m2 deck strength.

-

Certified Quality: All components are IACS compliant and delivered with individual test certificates.

-

-

SW-C7 Series Self-Elevating Platforms:

-

Primary Use: Nearshore marine construction (jetties, breakwaters, piling).

-

Heavy-Duty Capacity: Handles deck loads up to 400 mT.

-

Extended Reach: Maximum spud length of 38.5m, allowing operation in water depths up to approx. 28m.

-

Detailed Specifications Below!

-

-

SW-C9.5 Series Self-Elevating Platforms:

-

Largest Offering: Biggest of our self-elevating platforms.

-

Connective Design: Standardized floating modules coupled with a male/female pin connection system.

-

Ideal for: Heavy-duty construction (jetties, breakwaters), and various oil & gas applications.

-

Massive Support: Supported by four 75” diameter spud legs, each with a 600-ton capacity.

-

Automated Operation: Operated by synchronized hydraulic cylinders.

-

Detailed Specifications Below!

-

-

C1500 / C2000:

-

Advanced Design: Design complete for a 1500 or 2000 mT payload platform.

-

Class Approved: IACS class approval obtained.

-

-

-

Floating Systems:

-

Customizable Solutions: Versatile systems for security platforms, floating bridges, jetties.

-

Reliable Pontoons: Standardized, watertight, welded steel, buoyant pontoons for diverse floating applications.

-

KEY FEATURES & ADVANCED TECHNOLOGY

-

Modularity: Platforms support numerous applications: ports, jetties, renewables, dredging, oil & gas, temporary infrastructure.

-

Coupling System:

-

Safe & Easy: Designed for safe handling and transport.

-

High Strength: High-strength, low-alloy steel for simple, quick, rigid, positive locking with no loose parts.

-

Efficiency: Can be used while afloat, engaging top and bottom locks simultaneously, eliminating need to enter pontoons.

-

-

Eco Hydraulic Power Units:

-

Sustainable Choice: New units offer an E-power option for SW-C5 series.

-

Environmentally Friendly: Meets high emission standards for environmentally sensitive areas.

-

-

SW-C7 Jacking System:

-

Enhanced Performance: Upgraded cylinders for increased jacking speed.

-

Improved Safety: Central Control Cabin with automated operating system.

-

Powerful Movement: Four heavy-duty hydraulic cylinders with a 1.22-meter stroke.

-

Redundancy: Powerpack in 20' container with two diesel engines and two hydraulic pumps for redundancy.

-

Safety First: Full manual and local control at spudwells always available.

-

-

Transport & Assembly:

-

Easy Handling: Pontoons supplied with centrally located lifting lug and are self-stabilizing.

-

Logistics Friendly: Modules sized for transport by road, train, or ship.

-

ENGINEERING SUPPORT & WORKABILITY

-

In-House Expertise: Highly qualified engineers offer services to guide clients on operational and environmental matters.

-

Full Project Support: Engineers available through all project stages: tendering, preparation, and execution.

-

Specialized Studies Offered:

-

Floating stability, elevated stability, deck layout, dimensional analysis.

-

Strength calculations, hydrodynamic diffraction analysis, structural dynamic analysis.

-

Leg touch-down analysis, code checks, punch-through risk analysis.

-

Project equipment, propulsion analysis, and mooring analysis.

-

-

Advanced Software: Utilizing AutoCAD, Inventor, ANSYS, AQWA, and Delftship.

VERSATILE APPLICATIONS & CAPABILITIES

-

Shallow Draft:

-

Unique Combination: Shallow draft and high allowable deck loads.

-

Ideal For: Pipe and cable lay in shallow water, nearshore, and lakes, with drafts as low as 0.5m.

-

-

Renewables:

-

Stabilized Lifting: System stabilizes lifting spreads in landlocked areas ("spuds over the side").

-

Heavy Lifting: Allows large loads like crawler cranes up to 1250t for Wind Turbine Generator (WTG) installation.

-

-

Energy / Oil & Gas:

-

C-9.5 Series: Supports P&A (plug and abandonment), maintenance, repair, and drilling in nearshore and landlocked areas.

-

Security & Infrastructure: Jack-up barges can function as security platforms in oil fields.

-

Efficient Deployment: Modular platforms facilitate placing fully equipped land drilling rigs in shallow waters and swamp areas, often eliminating capital dredging and leaving no permanent footprint.

-

World's Biggest: Operates the world’s biggest modular jack-ups, capable of lifting over a 1000mT payload.

-

QHSE: QUALITY, HEALTH, SAFETY & ENVIRONMENT

-

Safety Focus: Essential element in all operations, with active risk assessment for people's health and safety.

-

Environmental Protection: Aware of environmental protection, especially in sensitive locations. Environmental Management System ensures environmentally friendly operations.

-

Quality Management: Documented Quality Management System ensures first-class products and service.

-

Certifications: Management meets ISO 9001, ISO 14001, and ISO 45001 standards.

-

Industry Affiliations: Member of IRO (supporting Offshore Energy supply in Netherlands) and IJUBOA (sets standards for safe and effective self-elevating platform operations worldwide).

FEATURED VESSEL: SW-C7 MODULAR SELF-ELEVATING PLATFORM

Is the SW-C7 suitable for heavy marine work? YES! It offers a 400 ton variable deck load capacity and a deck strength of 15 ton/m2, making it suitable for heavy-duty marine construction.

How much deck space is available? The platform provides a large 520 m² free deck space, allowing custom deck layouts tailored to your mission equipment and operating method without obstructions.

What water depths can the SW-C7 operate in? Depending on soil penetration and waves, it can operate in water depths up to 30 meters, with potential for increased depth in moderate environments.

How is the jacking system managed? Safe and efficient lifting, lowering, and repositioning are managed by a central or local controlled jacking system and a 4-point mooring system.

Is there redundancy for critical operations? YES! Redundancy is ensured through two independent hydraulic pump sets and manual control options for critical platform functions.

Technical Specifications (SW-C7):

-

General:

-

Type: SW-C7 Modular Self-Elevating Platform

-

Class (optional): Bureau Veritas or DNV - GL

-

-

Dimensions:

-

Length: 30.50 m

-

Breadth: 18.30 m

-

Depth: 2.13 m

-

Free deck area: 520 m²

-

-

Loads:

-

Variable deck load: 400 mT

-

Deck strength: 15 mT/m²

-

-

Jacking System:

-

Jacking type: Hydraulic, mechanical engaged

-

Jacking speed: 12 m/hr (full cycle, complete platform)

-

Jacking stroke: 1.22 meter

-

Jacking capacity: 300 mT/leg

-

Power: 240 kW, from two diesel-hydraulic pump sets

-

-

Spud Legs:

-

Leg length: 38.50 m (extendable)

-

Free length below hull: 32.00 m

-

Leg diameter: 1.22 m

-

-

Operational Conditions:

-

Maximum wave height Hmax: 3 m

-

Wind speed max: 50 km/hr

-

Current: 1 m/s

-

-

Survival Conditions:

-

Maximum wave height Hmax: 5 m (values may vary based on site and payload)

-

Wind speed: 120 km/hr

-

Current: 1 m/s

-

-

Platform Configuration and Design:

-

Composed of standardized floating modules connected via male/female system.

-

Supported by four spud legs within heavy-duty spud wells.

-

Hydraulic power unit and control cabin with flexible placement options.

-

All components sized for easy transport by road, rail, or sea.

-

Modular design allows customization of overall dimensions and spud leg lengths.

-

-

Jacking System Details:

-

Two hydraulically operated crossheads per spud well for locking/unlocking.

-

Vertical movement by four heavy-duty hydraulic cylinders (1.22-meter stroke, up to 250 bar).

-

Containerized hydraulic power pack (20' container) for simultaneous lifting/lowering.

-

Two diesel engines driving two hydraulic pumps for redundancy.

-

Central control system with remote PLC control for jacking.

-

Full manual and local control at spud wells for safety/backup.

-

-

Optional Features: Spud cans, 4-point mooring system, leg extensions, boat landing, propulsion, accommodation, mission equipment, jetting system, IACS classification.

-

QHSE Standards: Adheres to ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 (certified by Bureau Veritas).

FEATURED VESSEL: SW-C9.5 MODULAR SELF-ELEVATING PLATFORM

What is the SW-C9.5 designed for? The SW-C9.5 is our biggest self-elevating platform, ideal for heavy-duty jetty and breakwater construction works, nearshore oil & gas drilling, and as an accommodation platform.

What is its maximum deck load capacity? The platform can support deck loads up to 1000 mT, subject to free spud length, horizontal load, and environmental conditions.

How much free deck area does it offer? It boasts a large free deck area of approximately 910 m².

What is the operational water depth? With spud legs of 58m, it can operate in water depths up to 45m, depending on environmental conditions.

Does it have a central control system? YES! It features a central control system that allows for synchronous lifting and lowering.

Is it class approved? YES! It is delivered with IACS class notation.

Technical Specifications (SW-C9.5):

-

General:

-

Type: SW-C9.5 Modular Self-Elevating Platform

-

Class (optional): Bureau Veritas/DNV-GL

-

-

Main Dimensions:

-

Length: 36.60 m

-

Breadth: 27.40 m

-

Depth: 2.91 m

-

Free deck area: 910 m²

-

-

Loads:

-

Variable load (elevated): 1000 mT (subject to conditions)

-

Deck strength: 15 mT/m²

-

-

Jacking System:

-

Leg length: 58.0 m, with extension possible

-

Free length below hull: 48.0 m

-

Leg diameter: 75"

-

Spudcan diameter: 6.0 m (optional)

-

Jacking Type: Hydraulic, mechanically engaged

-

Jacking speed: 14 m/hr

-

Jacking capacity: 600 mT/leg

-

-

Mooring System:

-

Winches: 4x23m pull hydraulic winches

-

-

Environmental Conditions:

-

Installation conditions (Hmax touching): 1−1.4 m* (depending on soil)

-

Operational conditions (Hmax): 3.0−6.0 m | Wind: 50.0 km/hr | Current: 1 m/s

-

Survival conditions (Hmax): 3.0−8.0 m | Wind: 120.0 km/hr | Current: 1 m/s

-

*Indicated values are conservative and may vary; feasibility checks available.

-

-

Configuration and Design Details:

-

Supported by four 75" diameter spud legs, each individually operated by four synchronized hydraulic cylinders.

-

Specific spudwell capacity: 600 mT.

-

Spuds delivered in three parts for ease of transportation.

-

Standardized floating modules coupled via male pin/female connection.

-

Modules sized for easy transport by road, train, or ship.

-

Specific deck point load of each module: 15 mT/m².

-

Modular design allows overall dimensions to be adapted to customer needs.

-

-

Jacking System Operation:

-

Two hydraulically operated crossheads per spudwell for locking/unlocking.

-

Vertical movement by four hydraulic heavy-duty cylinders (1.2 m stroke, 140 bar).

-

Containerized hydraulic power pack for simultaneous lifting/lowering.

-

Silenced power packs with two 244 kW radiator-cooled diesel engines.

-

Central control system for synchronous lifting.

-

Spare hydraulic connectors for emergency or additional deck equipment.

-

-

Deck Equipment:

-

Safety railing around platform with sufficient access.

-

Four hydraulic operated winches on removable foundations:

-

Pulling force: 23 mT (first layer)

-

Holding force: 26 mT

-

Pulling speed: 9 m/min

-

Drum capacity: 264 m of Ø 32mm (4 layers)

-

-

Fairleads and deck sheaves for cable guidance.

-

-

QHSE Standards: Adheres to ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 (certified by Bureau Veritas).

Asking price: it will be revealed to very serious & committed buyers only upon full business & background disclosure.

COMMITMENT REQUIRED: To ensure mutual respect for time and resources, we require:

-

Clear Budget Levels: Aligned with international market rates.

-

End Buyer Background Disclosure: Serious named buyers only.

EMail: "Mr.Sher (VESSELS) Singapore - Malaysia - S&P" <sw@sher-worldwide.com>

/ "Mr.Sher (VESSELS) Singapore - Malaysia - S&P"<sherworldwidetrading@gmail.com>

T&Cs apply as per website. Details believed correct at the time of advertising. Vessels/items offered “as is where is,” subject to prior sale or withdrawal. SW not liable for errors or omissions and reserves the right to amend contents without notice.

#SherWorldwide #ModularJackup #SelfElevatingPlatform #ShipsForSale #MarineConstruction #OffshoreVessels #JackupBarge #HeavyLift #OilAndGas #RenewableEnergy #MarineEquipment #SWC7 #SWC95 #Vessels

No Record Found!